Tech Talk

Up-to-date information that helps you level up with today's ever growing plating industry.

RHL Associates, LLC is your go-to-expert for supplies, equipment and knowledge.

TEMPERATURE SENSOR LOCATION

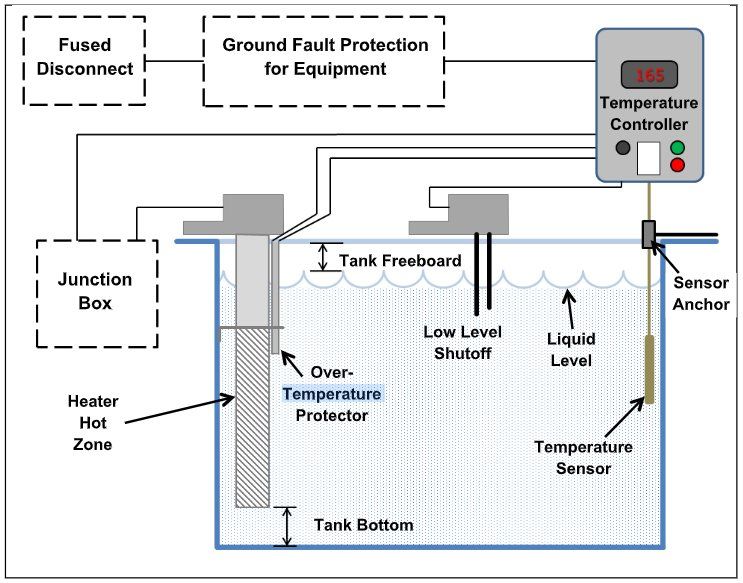

When controlling temperature in a process bath, the location of the temperature sensor is important. Whether the bath has forced circulation, air agitation or merely natural convective currents, there will be temperature gradients throughout the tank. For the line operator, the location of the temperature sensor should avoid dead zones or cold zones that would result in inaccuracy of the temperature controller. Here are a few tips to make sure the temperature sensor is placed in the optimum location.

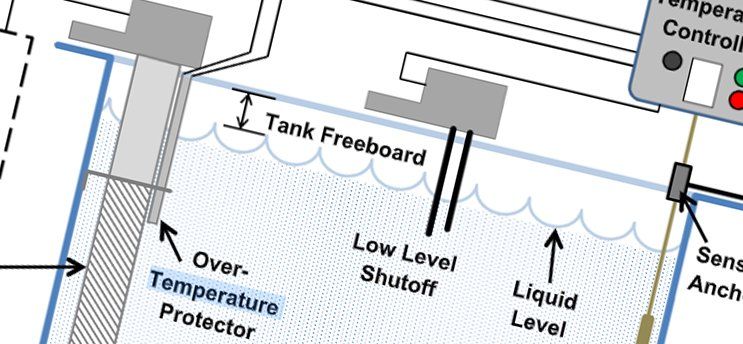

- Not too high. Do not locate the sensor so high that it could end up in the air if the liquid level in the bath were to drop. Typically the sensor should be a few inches below the minimum operating level of the tank.

- Not too low. The bottom of the bath is a notorious cold zone, due to natural convection which makes the heated liquid rise up. Never install the temperature sensor so low that it could sink below the bottom of the heater hot zone.

- Stay away from the heat. Installing the temperature sensor too close to the source of heat could place it in a convection zone that could be warmer than the rest of the bath.

- Close to the work. The temperature sensor should be close to the location where the parts will be processed. This will give a better indication of the temperature of the liquid where it is most important.

- Avoid obstructions. Installing the temperature sensor behind a large obstruction, tank weir, false wall, large anode plate, etc. may place it in a region which is blocked from circulating currents, again resulting in an inaccurate measurement.

- Stay put. The sensor position should be fixed to prevent it from drifting to other areas of the tank or getting tangled-up in the work. Sensor anchors or thermowell tubes are very affordable devices that will hold the sensor in the optimum location.

When controlling temperature in a process bath, the location of the temperature sensor is important. Whether the bath has forced circulation, air agitation or merely natural convective currents, there will be temperature gradients throughout the tank. For the line operator, the location of the temperature sensor should avoid dead zones or cold zones that would result in inaccuracy of the temperature controller. Here are a few tips to make sure the temperature sensor is placed in the optimum location.

- Not too high. Do not locate the sensor so high that it could end up in the air if the liquid level in the bath were to drop. Typically the sensor should be a few inches below the minimum operating level of the tank.

- Not too low. The bottom of the bath is a notorious cold zone, due to natural convection which makes the heated liquid rise up. Never install the temperature sensor so low that it could sink below the bottom of the heater hot zone.

- Stay away from the heat. Installing the temperature sensor too close to the source of heat could place it in a convection zone that could be warmer than the rest of the bath.

- Close to the work. The temperature sensor should be close to the location where the parts will be processed. This will give a better indication of the temperature of the liquid where it is most important.

- Avoid obstructions. Installing the temperature sensor behind a large obstruction, tank weir, false wall, large anode plate, etc. may place it in a region which is blocked from circulating currents, again resulting in an inaccurate measurement.

- Stay put. The sensor position should be fixed to prevent it from drifting to other areas of the tank or getting tangled-up in the work. Sensor anchors or thermowell tubes are very affordable devices that will hold the sensor in the optimum location.

Download the Process Technology PDF image to your desktop for future reference:

Call us today

for all your equipment and supply needs!

We're here everyday of the year to answer all your questions and to provide you with the expert knowledge you need.

RHL Associates accepts:

CORPORATE OFFICE

RHL Associates, LLC

11 Schooner Way

Marshfield, MA 02050 USA

CONTACT

T: (978) 273-8100

F: (978) 440-8133

rhl8100@aol.com

Nationwide USA

SUPPORT HOURS

7AM - 7PM

7 Days A Week

RHL Associates , LLC, Industries Served: Plating, Metal Finishing, Surface Finishing, Chemical Processing, Printed Circuit Board, Anodizing, Electropolishing, Jewelry, Semiconductor, Microelectronics, Photovoltaic. Representative States Served:AL, AZ, CA, CO, CT, DE, FL, GA, IL, IN, KS, KY, LE, MA, MD, ME, MI, MN, NH, NJ, NY, PA, RI, SC, TX, UT, VA, VT, WA, WI.

Logos and trademarks are the property of their respective owners, this includes equipment and product images.